This solution gasket has been developed based on a wealth of know-how accumulated for decades and results of many strict tests designed to solve many complex problems that occur onsite.

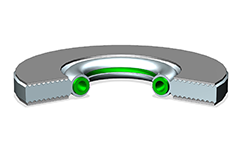

This product overcomes limitations of the existing gasket models such as buckling, filler oxidation in the air, product damage due to high load, leakage due to significant temperature departure, and leakage due to difference in the flange flatness. This solution gasket also maintains the sealing even under adverse conditions such as thermal expansion and contraction that require a high level of resilience, thermal impact, vibration, etc. as well as secures high sealing performance with no need for hot-bolting even in use of LNG/LPG at ultra-low temperature and pipelines at high temperature and high pressure.

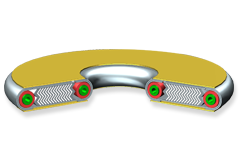

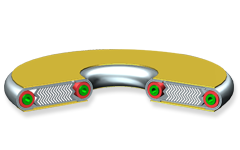

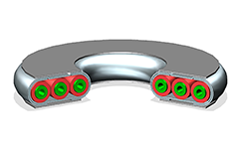

As the precise technical design is applied to the structure, including the double metal clad, spiral wound, O-ring, spring, and layer, this gasket model secures various advantages and exceeds the performance of any existing gaskets.

Hiflex metal gaskets are appropriate for critical environments where existing gaskets are not applicable such as hydrogen lines, heat exchangers that involve significant temperature fluctuation, lines that involve frequent leakage, etc. This model applies to every type of flanges and various industry sectors. Customized production for non-standard measurements and standard flanges available such as ASME, JIS, DIN, etc.